Description

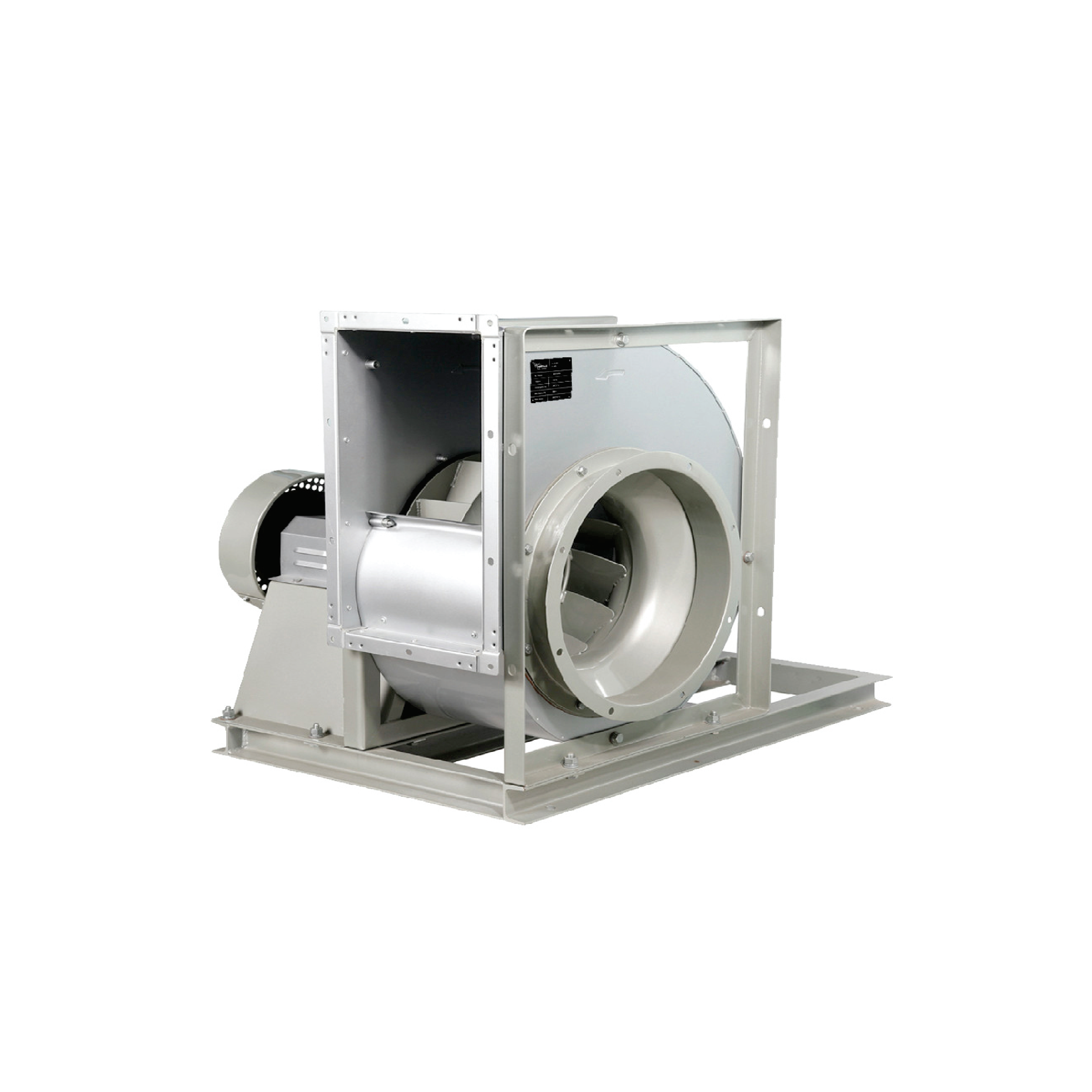

General Information:

The FCD centrifugal fans with forward/reverse blades are developed with modern technology.

They are designed to meet BS and ISO standards for air, acoustic and performance equivalent to BS,

AMCA and DIN standards. With advanced design for the advantage of fan: forward impeller, wide range of

applications, compact design, high efficiency, cost saving, high operating quality, low noise and quiet

running as well as low power consumption. These fans are ideal for use in central air conditioning systems,

in purifiers. The efficiency of all fans is guaranteed through specific volumetric figures at maximum

differential pressure. Excellent performance and minimal noise are the characteristics of this new series of

fans. They are also suitable for use in many other types of ventilation such as hotels, hospitals, schools,

commercial centers, etc.

Type Fan:

• FCD series: Forward curve centrifugal fan withsingle inlet single width.

Construction Information:

FCD series are mainly constructed of casing, impeller, bearing, shaft, frame, motor and inlet,

outlet flange.

Casing:

The housing is made of hot-galvanized corrugated iron according to EN 10142 or mild steel with epoxy paint. 304 or 316 stainless steel of the housing is available upon request. Modular design, easy to maintain and mount or remove left. Make sure the case is strong and stable.

Impeller:

The wing is designed with a forward curved radial format. The blades are made of hot-galvanized corrugated iron, successively ranked together in the form of goodness helping the wings achieve the highest aerodynamic profile in terms of performance and lowest noise. The blades are fixed to the impeller by means of rivets. Connecting makes the blade stiff and the blade structure does not change when the fan operates continuously at maximum capacity.

Backward curved radial impellers are made of high-grade cold-rolled epoxy coated sheet Balanced by ISO 1940 with G2.5mm/s quality standard.

Frame:

The frame of the R type exhaust fan is made of galvanized angle iron bars. The cutting and bending of the frame parts, as well as the TOX connections, are formed using a die to ensure high precision and rigidity of the frame.

The frames of type E and C ventilators are welded with angle steel and flat steel, cover by a polyester coating to ensure sufficient rigidity and strength.

Motors:

Motors incorporated are TEFC (Total Enclosed Fan Cooled), and airstream rated to IEC 34-1.

The characteristic is compact structure, short axial size low noise.

The motor is made of 100% copper winding and equipped with high quality Japanese ball bearing, high efficiency, low noise, maintenance free and long life. Power supply – single-phase or three-phase to accommodate a wide range of voltages and frequencies.

The standard motors have Class F and H enclosure class IP 55.

• IE1, IE2, IE3 and IE4 Efficiency Classes.

• High temperature motor (Class H): 250°C/2hrs or 300°C/2hrs.

• Explosion proof motor: Class F and IP55 or IP66 with completed ATEX 2014/34/EU and EN 50014, EN 50018 and EN50281-1-1.

Bearings

The bearings used in all Dyuniair centrifugal ventilators are high quality bearings and they have been selected to minimize ventilator noise. The bearings are pre-lubricated, sealed and self-centering. For type R exhaust fans, the bearings are fitted with anti-vibration washers.

For type E and C ventilators, self-aligning ball bearings are used, and k-type ventilator bearings are supplied with a lubricating accessory.

The service life of the bearing (L10) is more than 100,000 hours (L10 >= 100,000 hours). Limit values for speed and power are shown in the characteristic curve and should not be exceeded. Long-term quality is protected when general assembly and maintenance instructions for V-belt drives are provided.

Shaft

The shafts are made of 45 Cr carbon steel rods. Shafts are machined to very precise tolerances and they are fully tested to ensure an exact fit. They are coated after assembly to provide corrosion resistance. The shaft size shall be designed to meet the first critical speed of at least 1.4 times the maximum fan speed.

The shaft is equipped with keyways for the impeller hub and the belt pulley can be fitted at both ends of the shaft.

Stainless steel shaft will be used in anti-spark application.

Direction of Rotation

The exhaust fan can be divided into two rotation directions, they can be used carefree with LG left rotation or RD right rotation.

All versions can be easily rotated to install them in one of four directions 90°, 180° and 270°

The direction of the fan must be specified when ordering a fan with accessories that must be positioned in the preset direction

Inlet and Outlet Flange

The inlet flange are made of high grade cold-rolled sheet and painted with polyester coatings The outlet

flange is made of galvanized steel The connections of the flange components to each other and to the scroll are made using a TOX non-welding process This maintains a good flange appearance while also providing sufficient strength and rigidity.

Reviews

There are no reviews yet.